![]()

Next-generation cantilever with over one mega hertz resonance frequency is now available. ‘OmegaLever (Olympus Mega Hertz Cantilever)’, its high resonance frequency and low thermal noise vibration enables high speed and high resolution measurement.

(Common features in new silicon cantilever series)

The high resonance frequency with 1.6 MHz (Nominal) enables fast scanning measurement.

It can achieve to save your time of AFM data acquisition.

X line scanning 20 Hz

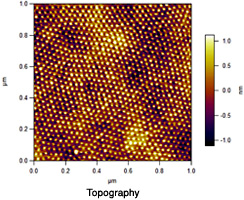

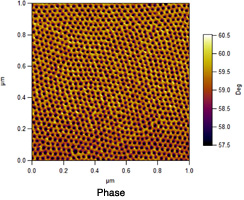

Kraton (SEBS) sample courtesy of Wendy van Zoelen and Rachel Segalman, UC Berkeley.

Topography and Phase imaged with Cypher AFM courtesy of Asylum Research

It’s low thermal noise of cantilever vibration enables high resolution measurement, which attributed to its high resonance frequency and high spring constant. It is worth while trying material research such as liquid-solid interface measurement.

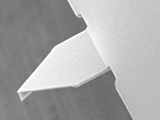

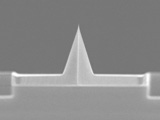

The apex of the tetrahedral probe is ideally point terminated.

The tetrahedral probe shows good symmetry viewed from the front. Considering the geometric feature, choose the fast scan (X) direction. Check Scan line profile and enlarged view of the tip apex.

The probe can be easily positioned at the exact point of your interest due to ‘Tip View’ structure.

The probe is located at the exact end of the cantilever so that the probe apex is not obscured during optical observations.

Thin gold film with the thickness of 70 nm is coated on the cantilever for reflecting light from the deflection sensor in the AFM equipment. High reflex for high S/N sensing can be expected.

The ideally vertical side-walls of the chip make tweezing easy and eliminate problems with chipping and debris.

Silicon Cantilevers, model OMCL-ACxxxxx-R3: available with 100 pre-separated chips.

Silicon Cantilevers, model OMCL-ACxxxxx-B3: available with 18 pre-separated chips.